When a building catches fire, every second counts. Behind the scenes, a critical component often goes unnoticed until disaster strikes: fire-resistant tapes. These specialized adhesives can mean the difference between a contained incident and catastrophic failure.

Fire-resistant tapes represent a fascinating intersection of materials science and safety engineering. They’re designed to maintain their integrity when conventional materials would fail, creating crucial barriers that slow or prevent flame spread. Unlike standard adhesives that melt or combust at relatively low temperatures, these specialized tapes can withstand extreme heat—often exceeding 1000°F—while maintaining their structural properties.

The evolution of these protective materials tells a compelling story of innovation. Early versions developed in the 1950s offered basic protection, but today’s advanced formulations incorporate intumescent compounds that actually expand when heated, creating an insulating char layer. This technological leap forward has revolutionized how we approach fire safety in everything from commercial buildings to aircraft manufacturing.

Industry standards have evolved alongside the technology. UL 94, ASTM E84, and NFPA 701 represent just a few of the rigorous testing protocols these materials must pass. These standards don’t just measure flame resistance—they evaluate smoke production, toxicity, and structural integrity under extreme conditions.

What makes these tapes truly remarkable is their versatility. From sealing HVAC ducts to protecting critical electrical systems, they serve as silent guardians in countless applications where failure simply isn’t an option.

The Ultimate Guide to Fire-Resistant Tapes

Fire-resistant tapes represent one of the most versatile yet underappreciated safety components in both industrial and residential applications. These specialized adhesive solutions offer critical protection against extreme temperatures and flame spread, with each variety engineered for specific performance characteristics. Understanding the different types of fire-resistant tapes, their unique features, and appropriate applications can make the difference between adequate protection and exceptional safety assurance.

Aluminum Foil Fire-Resistant Tapes

Aluminum foil fire-resistant tapes stand as the frontrunners in heat reflection technology. Constructed with a thin aluminum layer bonded to a high-temperature adhesive backing, these tapes create an effective thermal barrier by reflecting up to 95% of radiant heat.

Composition Breakdown:

- Core aluminum layer (typically 1-5 mil thickness)

- Heat-resistant acrylic or silicone adhesive

- Optional reinforcement mesh for durability

- Temperature resistance: 300°F to 600°F (149°C to 316°C)

The reflective properties make aluminum tapes particularly valuable for HVAC applications, where they seal ductwork while providing a fire-resistant barrier. Their malleability allows them to conform to irregular surfaces while maintaining their protective qualities.

The reflective nature of aluminum tapes doesn’t just resist fire—it actively redirects heat away from protected surfaces, creating a dual-action defense system.

These tapes excel in environments where flash fires or sudden temperature spikes pose risks, as their immediate reflection capability activates without any warm-up period.

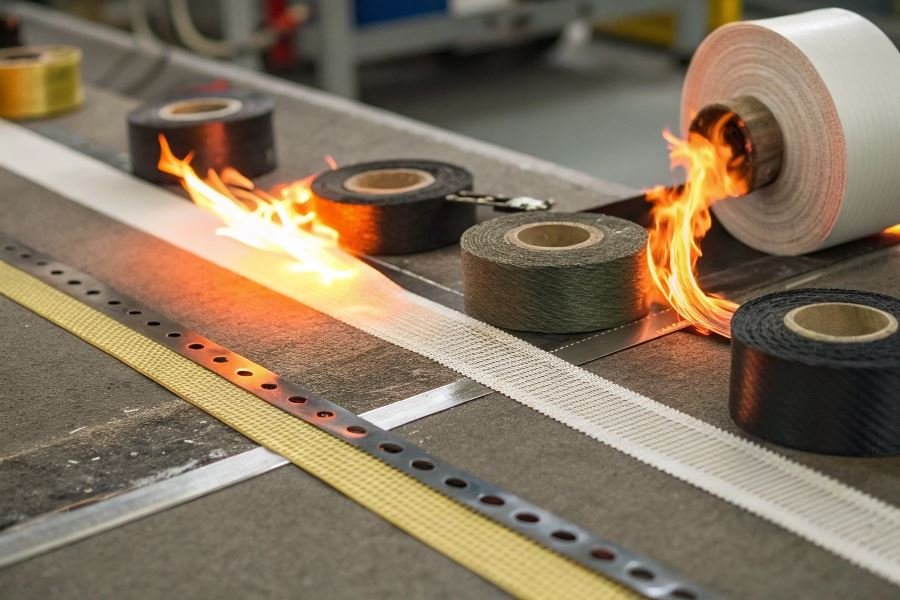

Fiberglass Fire-Resistant Tapes

When sustained high-temperature resistance becomes paramount, fiberglass fire-resistant tapes deliver exceptional performance. These tapes utilize woven fiberglass cloth impregnated with flame-retardant compounds to create a remarkably durable barrier.

Key Structural Elements:

- E-glass fiberglass weave (7-15 mil thickness)

- Flame-retardant chemical treatment

- Silicone or acrylic adhesive systems

- Temperature resistance: 500°F to 1000°F (260°C to 538°C)

| Property | Performance Level | Application Benefit |

|---|---|---|

| Tensile Strength | High | Maintains integrity during fire |

| Thermal Expansion | Low | Minimal warping at high temps |

| Smoke Generation | Minimal | Reduces secondary hazards |

| Flexibility | Moderate | Conforms to most surfaces |

Fiberglass tapes particularly shine in electrical applications, where they provide insulation while preventing flame spread along wire bundles. Their ability to maintain structural integrity even when directly exposed to flame makes them invaluable for critical infrastructure protection.

Ceramic Fiber Fire-Resistant Tapes

At the pinnacle of fire protection technology sit ceramic fiber tapes. These advanced solutions incorporate refractory ceramic fibers capable of withstanding extreme temperatures that would destroy conventional materials.

Advanced Protection Features:

- Alumina-silica ceramic fiber construction

- Non-combustible core material

- Temperature resistance: 1800°F to 2300°F (982°C to 1260°C)

- Low thermal conductivity (0.05-0.07 W/m·K)

The microscopic structure of ceramic fibers creates countless tiny air pockets that dramatically slow heat transfer. This property, combined with their inherent non-combustibility, makes ceramic tapes the go-to solution for the most demanding high-temperature applications.

These specialized tapes find their home in metallurgical operations, glass manufacturing, and aerospace applications where temperatures routinely exceed the capabilities of other fire-resistant materials. Their exceptional insulating properties also make them valuable in energy conservation applications where heat containment is as important as fire resistance.

Each type of fire-resistant tape offers distinct advantages based on its composition and structure, allowing for tailored protection solutions across countless industrial and commercial scenarios.

Where Fire Meets Function: Applications and Selection Guide

Industrial Powerhouses Need Protection

Fire-resistant tapes have become indispensable in industrial environments where heat, flame, and electrical hazards are constant companions. In HVAC systems, these specialized tapes secure ductwork and insulation while maintaining critical fire-resistance ratings. When temperatures spike, standard adhesives fail, but high-temperature silicone tapes maintain their grip up to 500°F (260°C).

The electrical sector relies heavily on these protective barriers, particularly in data centers and manufacturing facilities where downtime equals disaster. 3M Fire Barrier Tape applications have become standard practice for sealing cable trays and electrical penetrations, creating crucial firestops that prevent flame spread between compartments.

Manufacturing environments present unique challenges where molten metal, welding sparks, and high-temperature equipment create constant fire risks. Here, aluminum foil tapes with flame-retardant adhesives protect sensitive components and equipment, reflecting radiant heat while maintaining their structural integrity.

“The difference between a minor incident and a catastrophic failure often comes down to proper fire protection at connection points and transitions.”

Building Safety Beyond Code Compliance

Construction applications extend far beyond mere code compliance. Modern building techniques incorporate fire-resistant tapes as integral components of passive fire protection systems. In commercial construction, intumescent tapes expand when exposed to heat, sealing gaps around fire doors, windows, and structural joints that would otherwise allow smoke and flames to penetrate.

Residential applications have evolved significantly as homeowners recognize the value of enhanced fire protection. Flame-retardant tapes now seal HVAC ductwork, electrical boxes, and attic penetrations in premium homes, providing critical minutes of protection during a fire event.

Renovation projects present unique challenges where fire-resistant tapes offer practical solutions for upgrading existing structures. These specialized tapes can seal penetrations, wrap electrical conduits, and protect combustible materials without major structural modifications.

Selection Factors That Make or Break Performance

Choosing the appropriate fire-resistant tape requires understanding several critical factors:

| Selection Factor | Why It Matters | Common Mistake |

|---|---|---|

| Temperature Rating | Determines performance under heat stress | Selecting based on ambient rather than potential fire temperatures |

| Substrate Compatibility | Ensures proper adhesion to application surface | Ignoring material interactions that compromise adhesion |

| Certification Standards | Verifies performance claims through testing | Accepting manufacturer claims without third-party verification |

| Environmental Conditions | Accounts for humidity, UV exposure, and chemicals | Overlooking environmental factors that degrade performance |

The temperature rating must match both normal operating conditions and potential fire scenarios. Nashua Tape products, for example, offer ratings from 200°F to over 1000°F depending on the specific formulation.

Substrate compatibility determines whether the tape will maintain adhesion over time. Porous surfaces like concrete require different adhesive formulations than metal or plastic substrates. Testing adhesion on the actual application surface before full installation prevents costly failures.

Certification standards provide objective verification of performance claims. Look for UL listings, ASTM E84 flame spread ratings, and industry-specific certifications that match your application requirements.

The installation environment significantly impacts long-term performance. Tapes exposed to UV radiation, moisture, or chemical vapors require specialized formulations to maintain their protective properties throughout their service life.

Discover comprehensive insights into fire-resistant tape technologies, from aluminum foil to ceramic fiber options. Learn selection criteria and applications across industrial, HVAC, and construction sectors for optimal safety protection.

Discover comprehensive insights into fire-resistant tape technologies, from aluminum foil to ceramic fiber options. Learn selection criteria and applications across industrial, HVAC, and construction sectors for optimal safety protection.