Ever picked up a pair of dollar-store wire cutters and watched them crumple against a simple copper wire? That frustrating moment perfectly captures why proper tools aren’t just nice-to-have luxuries in radio amateur work—they’re essential foundations for success.

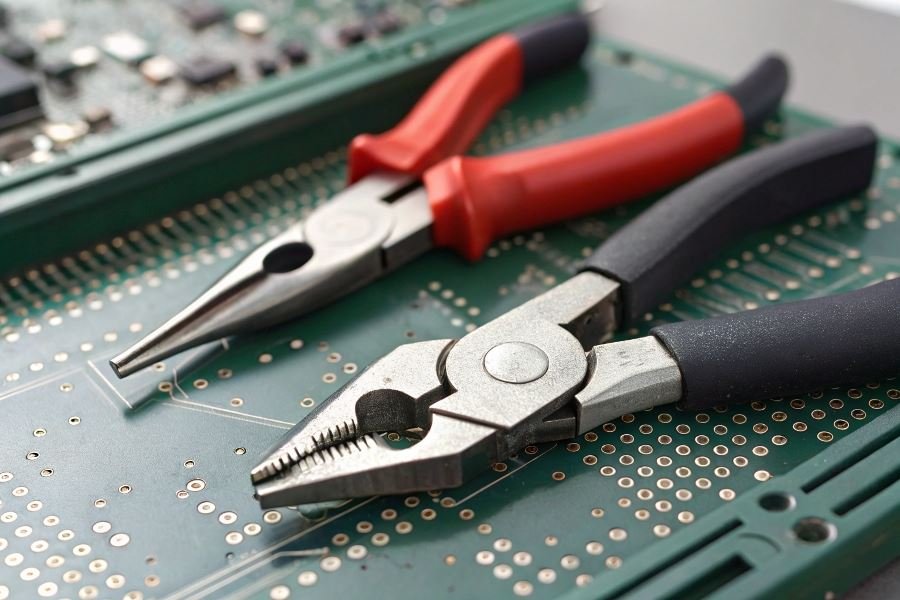

Radio hobbyists inhabit a world where precision matters. When you’re handling delicate circuit boards, trimming specialized wires, or modifying components, the difference between a clean cut and a mangled mess often comes down to the quality of your cutting tools. Yet many newcomers balk at equipment costs, not realizing that budget-friendly options exist that don’t sacrifice essential quality.

The right cutters transform tedious tasks into satisfying work. They reduce hand fatigue during long building sessions, prevent damage to expensive components, and deliver the precision needed for successful projects. But what exactly makes a cutter “right” for radio work?

First, look for flush-cut capability – the ability to trim wires without leaving sharp protrusions that can cause shorts. Second, consider comfort and leverage – you’ll be making hundreds of cuts during projects. Finally, prioritize durability – even budget options should last through multiple builds.

“The bitterness of poor quality remains long after the sweetness of low price is forgotten.” This old woodworker’s wisdom applies perfectly to radio amateur tools.

The good news? You don’t need to spend a fortune. Several manufacturers now offer entry-level precision cutters that deliver professional results without the professional price tag.

Precision on a Budget: Top 3 Cutters Every Radio Amateur Needs

When building your first radio kit or repairing equipment, the quality of your hand tools can make the difference between frustration and success. Finding budget cutters for beginner radio amateurs: what to choose for a novice doesn’t have to be overwhelming when you know what features actually matter for the work you’ll be doing.

Let’s dive into the three essential cutting tools that deliver professional results without emptying your wallet. Each serves a specific purpose in your growing toolkit, and investing in the right ones now will save you countless headaches down the road.

Entry-Level Precision Wire Cutters Under $30

The foundation of any radio amateur’s toolkit starts with a reliable pair of precision wire cutters. The Hakko CHP-170 ($8-12) stands as the undisputed champion in this category, offering Japanese-steel precision at a price that seems almost unfair. With flush-cutting capability and comfortable grips, they handle 16-26 AWG wire with remarkable ease.

For slightly more demanding work, the Klein Tools D275-5 ($25-28) provides additional cutting power while maintaining precision. The induction-hardened cutting edges stay sharp significantly longer than budget alternatives.

Key features to demand in entry-level cutters:

- Flush-cutting capability (essential for PCB work)

- Spring-loaded handles to reduce hand fatigue

- Cutting edges that align perfectly when closed

- Comfortable grips that won’t slip when your hands get sweaty

Multi-Purpose Cutting Tools for Daily Use

When you need versatility without sacrificing quality, multi-purpose cutting tools earn their keep. The IRWIN VISE-GRIP Multi-Tool ($20-25) combines needle-nose pliers, wire cutters, and strippers in one compact tool. This 3-in-1 approach saves precious workbench space and handles 90% of cutting tasks you’ll encounter.

For those who prefer dedicated tools with multiple cutting options, the DOWELL 10-22 AWG Wire Stripper ($15-18) includes precision cutting edges alongside stripping capabilities for various wire gauges.

What separates quality multi-purpose tools from disappointing ones:

| Feature | Budget-Friendly Signs of Quality | Red Flags |

|---|---|---|

| Pivot Point | Smooth action with minimal play | Wobbles or sticks when opening/closing |

| Cutting Edges | Hardened steel with precise alignment | Visible gaps when closed |

| Handle Comfort | Ergonomic with non-slip coating | Hard plastic that causes hand fatigue |

| Construction | Solid metal throughout | Plastic components in high-stress areas |

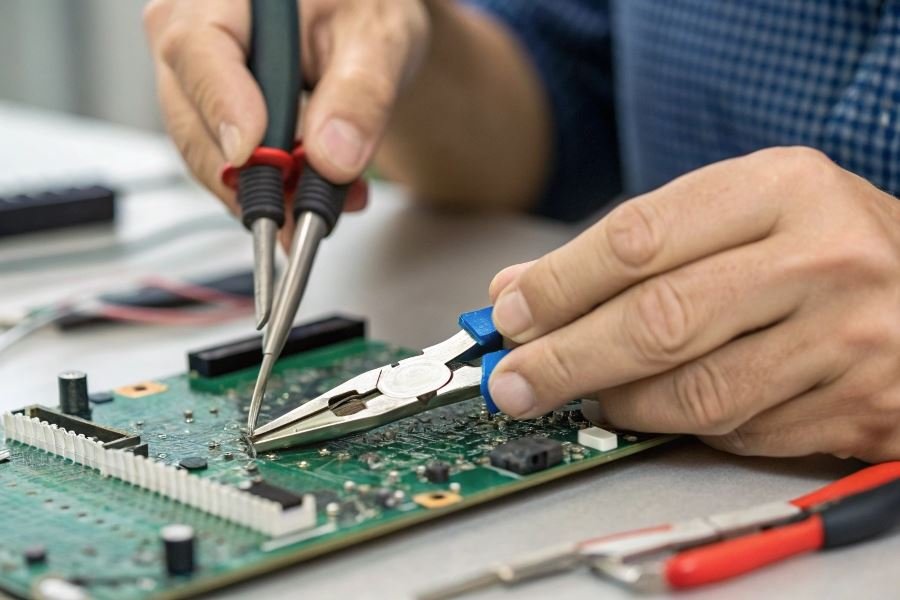

Specialized Flush Cutters for PCB Work

When working with printed circuit boards, standard cutters simply won’t do. The Engineer SS-02 ($25-29) represents the gold standard for PCB work, with its ultra-flush cutting edge that leaves virtually no component lead stub—critical for preventing shorts on densely packed boards.

For an even more budget-friendly option, the Plato 170 ($18-22) delivers impressive performance for component lead trimming. Its unique shearing action cuts cleanly through copper leads without the “ping” that sends tiny metal fragments flying across your workspace.

Why specialized flush cutters matter:

- They cut component leads flush to the board surface

- The cutting action doesn’t stress solder joints

- Precision tips reach into tight spaces between components

- They’re designed specifically for soft copper wire, not hardened steel

Remember that investing in quality tools now—even on a budget—means you won’t be replacing them next month. Each of these recommendations balances affordability with the precision that radio work demands, giving you room to grow your skills without outgrowing your tools.

Cutting Through the Noise: Budget Tools for Radio Beginners

Radio amateurs entering the hobby often overlook the importance of quality cutting tools. Yet these humble implements can make the difference between clean connections and frustrating failures. Let’s explore how to select, maintain, and know when to upgrade your essential cutting arsenal without breaking the bank.

Match Your Cutter to Your Mission

Different radio projects demand different cutting solutions. Understanding this relationship saves both money and headaches:

Wire Cutters: The foundation of any radio amateur’s toolkit. For beginners working with 18-24 AWG wire, the Klein Tools D275-5 diagonal cutters offer remarkable precision at under $15. Their spring-loaded design reduces hand fatigue during extended building sessions.

Precision Flush Cutters: When working on PCB components or surface-mount technology, standard wire cutters won’t cut it (pun intended). The IGAN-P6 flush cutters provide the necessary precision for trimming component leads without damaging circuit boards.

Cable Strippers: For coaxial work, automatic strippers like the Coax-Prep 6 eliminate guesswork by consistently removing the correct amount of insulation and shielding.

The right tool transforms frustrating tasks into satisfying accomplishments, especially when building your first dipole antenna or assembling a QRP transceiver kit.

Extending Cutter Lifespan Through Proper Care

Budget doesn’t have to mean disposable. With proper maintenance, even affordable cutters can deliver years of reliable service:

- Clean after each use: Remove wire fragments and debris with compressed air or a soft brush

- Apply light oil: A drop of 3-in-1 oil on pivot points prevents rust and ensures smooth operation

- Store properly: Keep tools in a dry environment, ideally in a tool roll or case with individual slots

- Mind your materials: Even budget cutters can handle copper and aluminum, but steel wire will quickly dull cutting edges

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Cleaning | After each use | Prevents corrosion, maintains precision |

| Oiling | Monthly | Reduces friction, extends lifespan |

| Edge inspection | Quarterly | Identifies wear before it affects performance |

| Tightening hardware | Semi-annually | Maintains proper tension and alignment |

The Upgrade Pathway

Budget tools serve admirably for beginners, but recognizing when to upgrade is crucial for advancing your radio projects:

Signs it’s time for professional-grade cutters:

- You’re regularly working with hardened materials like steel guy wire

- Precision requirements have increased (building SDR components or microwave circuits)

- Hand fatigue becomes noticeable during longer building sessions

- You’re experiencing inconsistent cuts that affect signal quality

The transition from beginner to intermediate often coincides with moving from $10-20 cutters to $30-50 professional-grade options like the Xcelite MS54 precision cutters or Hakko CHP-170 micro cutters.

Professional tools aren’t just about durability—they deliver consistent results that directly impact the performance of your radio projects.

When upgrading, don’t discard your budget tools. They remain valuable for field repairs or lending to curious friends just discovering the fascinating world of amateur radio. Remember that even legendary radio operators started with basic tools—it’s skill and knowledge that ultimately make the difference.

Discover the top 3 affordable cutting tools essential for new radio enthusiasts. Learn how to select quality wire cutters, multi-purpose tools, and PCB flush cutters that deliver precision without breaking the bank.

Discover the top 3 affordable cutting tools essential for new radio enthusiasts. Learn how to select quality wire cutters, multi-purpose tools, and PCB flush cutters that deliver precision without breaking the bank.