When flames threaten, what stands between safety and disaster might be thinner than a credit card.

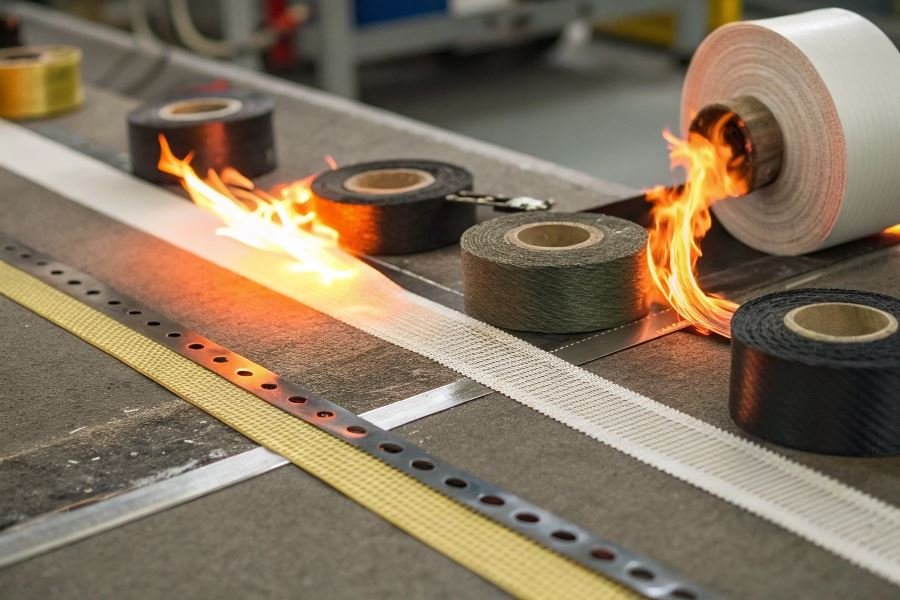

Fire protection tapes represent one of building safety’s most overlooked yet critical components. These specialized materials create fire-resistant barriers around pipes, cables, and structural elements, preventing flame spread and maintaining structural integrity during those crucial minutes when evacuation and emergency response occur.

The effectiveness of these protective barriers hinges entirely on their service life—a factor that varies dramatically between products and installation environments. A tape that deteriorates prematurely creates a dangerous false sense of security, potentially compromising an entire building’s fire safety system when it matters most.

What determines how long fire protection will actually protect?

Several critical factors influence durability:

- Environmental exposure: Humidity, temperature fluctuations, and UV exposure can degrade adhesives and backing materials

- Installation quality: Improper application creates weak points where protection fails first

- Material composition: Intumescent vs. non-intumescent formulations respond differently to aging

- Mechanical stress: Vibration and movement in building systems accelerate wear

The regulatory landscape provides essential guidance through standards like ASTM E84 and UL 723, which evaluate flame spread and smoke development. However, these tests primarily measure performance when new—not after years of service. The gold standard for certification comes from Underwriters Laboratories (UL), whose listings require rigorous testing under accelerated aging conditions.

Industry leaders have responded with innovations like silicone-based formulations that maintain flexibility and adhesion for 15+ years, significantly outperforming traditional acrylic options that may require replacement in as little as 5 years.

The difference between adequate and exceptional fire protection often comes down to understanding these service life variables—knowledge that transforms a simple purchasing decision into a critical safety investment.

The Science Behind Fire Protection Tape Longevity

Fire protection tapes represent a critical investment in building safety, but not all options deliver equal performance over time. When evaluating these essential safety components, understanding the factors that determine service life can make the difference between reliable protection and premature failure.

The service life of fire protection tapes depends on multiple interconnected factors that building professionals must carefully consider. From material composition to environmental conditions and installation practices, each element plays a crucial role in determining how long these protective barriers will maintain their fire-resistant properties. Let’s examine what truly matters when selecting fire protection tapes designed to stand the test of time.

Material Composition Defines Performance

The foundation of any durable fire protection tape lies in its material composition. High-performance intumescent tapes contain specialized compounds that expand when exposed to heat, creating an insulating barrier that prevents fire spread.

Graphite-based formulations typically offer superior longevity compared to conventional options, with some premium products maintaining effectiveness for 15+ years. These advanced materials react more predictably during fire events while resisting degradation during normal conditions.

The difference between standard and premium compositions becomes apparent when examining aging test results:

| Material Type | Average Service Life | Performance After Aging |

|---|---|---|

| Standard Mineral Fiber | 5-7 years | Moderate degradation |

| Graphite-Enhanced | 10-15 years | Minimal performance loss |

| Ceramic-Based | 15-20+ years | Negligible degradation |

Products from manufacturers like 3M Fire Barrier and Hilti Firestop incorporate proprietary technologies that significantly extend service life through enhanced chemical stability.

Environmental Factors That Challenge Durability

Even the most advanced fire protection tapes face challenges from environmental conditions that accelerate aging and degradation.

Temperature fluctuations create expansion and contraction cycles that stress adhesive bonds and material integrity. Tapes rated for extreme temperature variations (-40°F to 300°F) typically demonstrate superior longevity in real-world applications.

Humidity exposure represents another significant threat, particularly in:

- Coastal environments with salt-laden air

- Industrial settings with chemical vapors

- Areas with seasonal humidity swings

UV radiation gradually breaks down polymers and binding agents in many fire protection materials. For exterior applications or areas with significant natural light, selecting tapes with UV inhibitors extends service life by up to 40% compared to standard formulations.

Installation Quality: The Hidden Longevity Factor

The most overlooked determinant of fire protection tape longevity isn’t the product itself—it’s how it’s installed.

Proper surface preparation removes contaminants that would otherwise prevent proper adhesion. Studies show that inadequate surface cleaning reduces service life by 30-50%, regardless of tape quality.

Compression factors significantly impact performance over time:

| Compression Level | Effect on Service Life |

|---|---|

| Under-compressed | Premature failure, gaps form |

| Properly compressed | Optimal service life |

| Over-compressed | Material damage, reduced effectiveness |

Application temperature ranges must be strictly observed. Installing fire protection tapes outside manufacturer-specified temperature windows (typically 40°F-100°F) dramatically reduces long-term performance as adhesives fail to properly bond.

Professional installation by certified technicians typically results in 25-40% longer service life compared to DIY applications, making it a worthwhile investment for critical fire barriers that must perform reliably for years to come.

Selecting Fire Protection Tapes That Last

Fire protection isn’t just about meeting code requirements—it’s about creating lasting safety infrastructure that performs when you need it most. The durability of fire protection tapes can literally be the difference between containment and catastrophe. Let’s dive into the three critical factors that separate exceptional fire protection tapes from merely adequate ones.

Performance ratings that actually matter

When evaluating fire protection tapes, certification is your first line of defense against substandard products. The gold standard remains UL Listings, particularly the UL 1479 for through-penetration firestops and ASTM E814 for fire tests. These aren’t just fancy acronyms—they represent rigorous testing under extreme conditions.

What separates exceptional tapes from mediocre ones? Look for:

- F-Ratings measuring containment capability (minimum 1-hour, 2-hour preferred)

- T-Ratings indicating temperature transfer resistance

- L-Ratings for air leakage performance

The most durable options typically carry multiple ratings and have been tested in various installation scenarios. Products from manufacturers like 3M Fire Barrier often provide comprehensive documentation showing performance across different substrates and environmental conditions.

Industry insight: Tapes that maintain their integrity after accelerated aging tests (500+ hours) typically outperform competitors by 3-5 years in real-world applications.

Manufacturer reputation and warranty strength

The fire protection industry separates into two camps: established innovators with decades of testing data and newer entrants with aggressive claims but limited track records.

Premium manufacturers typically offer:

| Manufacturer Tier | Typical Warranty | Field Support | Installation Training |

|---|---|---|---|

| Top-tier | 10+ years | 24/7 technical support | Comprehensive certification |

| Mid-tier | 5-7 years | Business hours only | Basic training materials |

| Economy | 1-3 years | Limited/email only | Self-service documentation |

Companies like Hilti and STI Firestop have built reputations on extensive R&D and field testing. Their warranties often cover not just product replacement but also remediation costs—a critical consideration when calculating true lifetime value.

Premium vs standard tapes economics

The initial sticker shock of premium fire protection tapes ($75-150 per roll vs. $30-60 for standard options) often leads to short-sighted purchasing decisions. However, the math changes dramatically when considering:

- Replacement frequency: Premium tapes typically require replacement every 15-20 years versus 7-10 years for standard options

- Installation labor: Higher-quality tapes often require less material and installation time

- Inspection costs: Better documentation and longer-lasting performance mean fewer failed inspections

The true cost differential shrinks considerably when calculated over a building’s lifecycle.

For commercial applications, premium intumescent tapes from manufacturers like Tremco might cost 60-80% more upfront but deliver 100-150% longer service life. The calculus becomes even more favorable when considering the disruption cost of replacement in occupied buildings.

The most durable fire protection tapes combine superior material science with installation-friendly design. They maintain flexibility while resisting environmental degradation, and they come backed by manufacturers who stand behind their performance claims with meaningful warranties and field support.

Discover how to select fire protection tapes with maximum longevity. Learn key durability factors, material composition impacts, and essential selection criteria to ensure optimal building safety and long-term performance.

Discover how to select fire protection tapes with maximum longevity. Learn key durability factors, material composition impacts, and essential selection criteria to ensure optimal building safety and long-term performance.