When flames engulf a structure, the difference between containment and catastrophe often comes down to minutes—or even seconds. Behind the scenes, specialized materials work silently to buy that precious time, with fire protection tapes standing as frontline defenders in modern building safety systems.

Fire protection tapes represent specialized adhesive products engineered to maintain structural integrity during fire events. Unlike standard construction materials that quickly succumb to heat, these tapes activate under fire conditions, expanding to seal gaps, joints, and penetrations that would otherwise allow flames and toxic smoke to spread throughout a building. Their primary purpose? Creating compartmentation—the strategic isolation of fire to its point of origin.

Testing standards tell the real story behind a tape’s performance capabilities. The most rigorous evaluations include ASTM E84 for surface burning characteristics, UL 263 for fire resistance ratings, and ASTM E1966 for joint systems. These aren’t merely technical specifications—they’re the difference between a tape that performs as promised during an emergency and one that fails when lives depend on it.

The selection process requires precision. A tape suitable for electrical conduit penetrations might prove inadequate for HVAC ductwork. Factors including temperature rating (typically ranging from 150°F to over 2000°F), expansion ratio, smoke development, and installation environment all determine whether a specific tape will provide the necessary protection for your application.

“The right fire protection tape in the right application isn’t just about code compliance—it’s about creating a comprehensive defense system that responds intelligently to fire threats.”

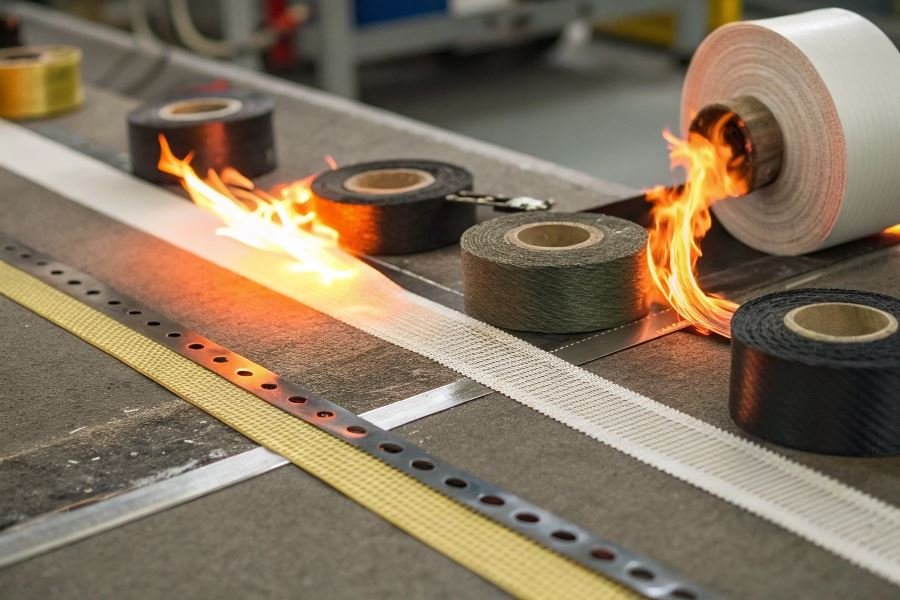

Fire Protection Tapes: The Ultimate Performance Showdown

When buildings face the fury of flames, fire protection tapes stand as silent guardians between safety and disaster. These specialized materials represent critical components in modern fire safety systems, with each type offering distinct advantages in specific applications. Let’s dive into the performance characteristics that set these fire-resistant champions apart.

Intumescent Tapes: The Expanding Defenders

Intumescent fire protection tapes represent one of the most fascinating innovations in passive fire protection. These remarkable materials remain dormant until activated by heat, at which point they undergo a dramatic transformation.

When exposed to temperatures typically ranging from 300°F to 400°F (149°C to 204°C), intumescent tapes expand to up to 40 times their original thickness. This expansion creates a robust char layer that acts as a formidable barrier against flame spread. The comprehensive comparison of fire-resistant characteristics of different types of fire protection tapes reveals that intumescent varieties excel particularly in sealing gaps and joints that would otherwise allow fire to penetrate compartment walls.

What truly distinguishes quality intumescent tapes is their smoke suppression capability. Premium products not only block flames but also minimize the production of toxic gases—often the deadliest aspect of building fires. The expansion process consumes oxygen that would otherwise feed the fire, creating a dual protective mechanism.

Ceramic Fiber Tapes: The Temperature Warriors

Ceramic fiber tapes stand as the undisputed champions of extreme temperature resistance. Unlike their intumescent counterparts, these tapes don’t expand but instead provide:

- Temperature resistance up to 2300°F (1260°C)

- Exceptional thermal insulation properties

- Superior dimensional stability under prolonged heat exposure

The ceramic fibers, typically composed of alumina-silica blends, maintain their structural integrity even when subjected to direct flame impingement. This makes them particularly valuable for protecting critical infrastructure like electrical conduits and structural steel components.

| Property | Performance Rating | Applications |

|---|---|---|

| Heat Resistance | Exceptional (up to 2300°F) | HVAC systems, Electrical conduits |

| Compression Recovery | Good to Excellent | Expansion joints, Gaskets |

| Moisture Resistance | Moderate | Indoor applications |

| Longevity | 15+ years | Permanent installations |

The durability of ceramic fiber tapes extends beyond fire resistance—they withstand vibration, moisture, and many chemicals, making them ideal for industrial environments where multiple stressors exist simultaneously.

Graphite-Based Tapes: Flexible Protection Powerhouses

Graphite-based fire protection tapes bring unique properties to the fire safety arsenal. Their standout characteristics include:

Exceptional thermal conductivity allows these tapes to quickly dissipate heat away from protected surfaces, preventing localized hotspots that could compromise structural integrity. Despite this conductivity, they create an effective barrier against flame spread.

Flexibility remains unmatched even after exposure to extreme temperatures. While ceramic tapes may become brittle after fire exposure, graphite-based options maintain their adaptability, making them ideal for applications involving movement or vibration.

Under extreme heat conditions (typically above 600°F/315°C), graphite-based tapes exhibit intumescent-like properties, expanding slightly to fill gaps created by material shrinkage during a fire. This hybrid behavior provides comprehensive protection across various fire scenarios.

Their electrical conductivity offers an added benefit in certain applications—the ability to prevent static buildup while simultaneously providing fire protection, a dual functionality that makes them particularly valuable in electronics manufacturing and data centers.

Each tape type presents distinct advantages depending on the specific fire protection requirements, making proper selection crucial for effective fire safety strategy implementation.

Making the Right Choice: Fire Protection Tape Selection Criteria

Application-specific considerations for optimal protection

Selecting the right fire protection tape requires understanding how different environments demand specific fire-resistant characteristics. In industrial settings where temperatures can exceed 1000°F, intumescent tapes that expand when exposed to heat create crucial fire barriers. Meanwhile, commercial buildings often benefit from ceramic fiber tapes that provide excellent thermal insulation while maintaining structural integrity.

The application surface also dramatically impacts performance. Metal substrates typically require different adhesion properties than wood or plastic materials. For example, silicone-based fire protection tapes excel on metal surfaces in high-temperature environments, while acrylic-based options often perform better on porous materials like concrete or drywall.

Installation location matters tremendously. Exterior applications demand weather-resistant properties alongside fire protection. Indoor applications in humid environments like commercial kitchens require moisture-resistant formulations to maintain effectiveness over time.

The most expensive fire protection tape isn’t always the best choice—it’s about matching specific fire-resistant characteristics to your exact application requirements.

Premium vs standard solutions: The real cost equation

When evaluating fire protection tapes, the initial price tag tells only part of the story. Premium solutions from manufacturers like 3M or Hilti typically command price premiums of 30-45% over standard alternatives, but often deliver superior longevity and performance.

Consider this cost comparison of typical fire protection solutions:

| Protection Type | Initial Cost ($/sq ft) | Lifespan (years) | Annual Cost | Additional Benefits |

|---|---|---|---|---|

| Premium Intumescent | $3.75-5.50 | 15-20 | $0.25-0.37 | Higher expansion ratio, faster reaction time |

| Standard Intumescent | $2.25-3.25 | 8-12 | $0.28-0.41 | Basic code compliance |

| Premium Ceramic | $4.25-6.00 | 20+ | $0.21-0.30 | Superior thermal stability, minimal degradation |

| Standard Ceramic | $2.50-3.75 | 10-15 | $0.25-0.38 | Adequate thermal resistance |

The true value equation extends beyond purchase price. Premium solutions often require less maintenance, provide longer service intervals, and offer enhanced performance during actual fire events. For critical infrastructure or high-occupancy buildings, the additional investment typically yields substantial long-term returns through reduced replacement cycles and potentially lower insurance premiums.

Tomorrow’s fire protection innovations

The fire protection tape industry is experiencing remarkable technological advancement. Nano-engineered materials are creating thinner, more effective barriers that outperform traditional solutions while requiring less space—critical for retrofit applications in existing structures.

Smart fire protection tapes incorporating temperature-sensitive indicators are emerging, allowing for visual verification of tape condition without specialized equipment. Some advanced formulations from Specified Technologies Inc. now include color-changing properties that signal when replacement is needed.

Sustainability is driving innovation as well. New environmentally friendly formulations eliminate halogenated compounds while maintaining or improving fire-resistant characteristics. These green alternatives reduce toxic smoke production during fire events while offering comparable protection ratings.

Perhaps most exciting is the development of multi-functional fire protection tapes that combine fire resistance with additional properties like acoustic dampening, vibration control, or electromagnetic shielding. These hybrid solutions offer cost efficiencies by reducing the number of different products needed for comprehensive building protection.

The integration of fire protection systems with building management technology is creating opportunities for real-time monitoring and predictive maintenance, fundamentally changing how we approach fire safety in commercial and industrial environments.

Discover the critical differences between intumescent, ceramic fiber, and graphite-based fire protection tapes. Learn how to select the right fire-resistant solution based on expansion properties, heat thresholds, and application requirements for optimal building safety.

Discover the critical differences between intumescent, ceramic fiber, and graphite-based fire protection tapes. Learn how to select the right fire-resistant solution based on expansion properties, heat thresholds, and application requirements for optimal building safety.